Concrete Finishes – Differences Explained

Concrete Finishes for Flatwork come in four main types:

- Slick Troweled Concrete Finish

- Broom Concrete Finish

- Stamped Concrete Finish

- Exposed Aggregate Concrete Finish

Slick Troweled Concrete Finish

- Typically, slick troweled concrete can be found as garage floors, basement floors, warehouse floors and covered front porches.

- Slick Troweled Concrete is created when a steel hand trowel or machine is used by the cement mason to close the exposed surfaces of the concrete project.

- More labor and time is required to produce the Slick Troweled Concrete Finish as the concrete needs to be hard enough for the cement finisher to walk, kneel on, ride or walk behind a mechanical finish trowel machine.

- Once the concrete becomes hard enough to stand, kneel, walk or ride on – there is a limited window of time the finisher has to ‘close the surface’ before the concrete hardens beyond being able to be worked.

The benefits of Slick Troweled Concrete is ease of cleaning.

- Slick troweled concrete is easy to sweep, mop or hose it down and squeegee off.

Slick Troweled Concrete’s drawback is that when it’s damp or wet it’s – well – slick.

- There is minimal traction to this finished product if it’s wet or your shoes are wet from rain or snow.

Broom Concrete Finish

- Broom Finished Concrete is similar to Slick Troweled Concrete in that both contain the same ingredients.

- The surface of Broom Finished Concrete gets closed typically with a ‘bull float’ before a specialty broom attachment is pulled across the surface to create a distinct rough texture.

- This method does not require that the finisher close the surface by hand.

- Although, your better concrete companies’ Broom Finished Concrete Projects are closed by hand or with a ‘Fresno’ before the broom finish is created.

- While an ‘an extra step’, this provides a very consistent texture that is very appealing to the eye and touch.

The benefits of Broom Finished Concrete are:

- Good traction.

- Visually appealing.

- Reasonable price point.

The drawback to Broom Finished Concrete due to rough texture

- Little harder to clean.

- Depending on the degree of ‘roughness’ – may not be pleasant to bare feet or little one’s knees.

- If this is a concern to you be sure to discuss ‘light broom finish’ with your concrete contractor well before the day of pour.

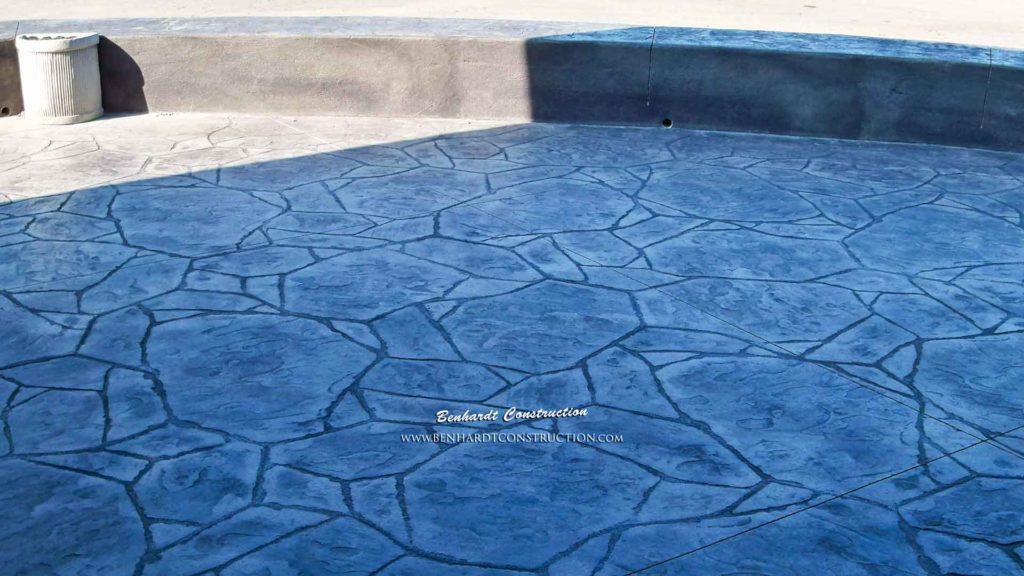

Stamped Concrete Finish

- Stamped Concrete can be finished to mimic stone, brick, wood and many other materials.

- A variety of color dyes can be mixed into the concrete. Release agents for the stamps have color options also.

For a deeper dive into Stamped Concrete

Be sure to check out my

- If there is to be a color in the concrete itself it will be added at the concrete plant or on the job site.

- The concrete will also contain a smaller aggregate to ensure uniform consistency throughout the stamp and allow for the aggregate to not be pushed too far below the surface by the stamp.

- The concrete will typically be hand worked by a finisher(s) before the stamping starts.

- Up to this point – the process for finishing Stamped Concrete is very similar to slick trowel and broom finish concrete.

- Very large and heavy rubber mats with the stamped concrete texture or stamped concrete pattern you chose will be placed in a pattern after the release (think: using flour when making biscuits to keep from sticking) has been spread across the surface area.

- The stamping takes place and the molded textures create the desired effect in the surface of the concrete. The stamps are removed one at a time and placed in a new location to continue stamping the surface of the concrete.

- This process continues until the entire surface has been stamped properly.

- Typically the following day – control joints are saw cut into the surface of the stamped concrete and then power washed to remove any extra release agent from the surface of the concrete before Concrete Sealer can be applied after allowed to dry.

Please Note

ALL Stamped Concrete

REQUIRES Sealing

- — As soon as possible after saw cutting, cleaning of excess release agent and the surface allowed to to fully dry.

- — Sealing protects your concrete overall BUT also ‘SEALS’ in your release color; adding to it’s longevity.

Stamped Concrete Benefits:

- The end results are stunning!

- Works great around:

- Pools,

- Outdoor kitchens and patios,

- Wineries,

- Bistro outdoor dining.

Stamped Concrete Drawbacks:

- Higher price point

- Requires frequent sealing to protect coloring.

- Traffic,

- Weather,

- Amount of Direct Sunlight.

- Are a few of the variables affecting maintenance frequency of sealing stamped concrete.

- Exposed Aggregate Concrete utilizes a different aggregate than that of Slick Troweled or Broom Finished.

- As the aggregate is revealed or ‘exposed’ through a multi step process that involves the removal of the cement ‘paste’ from the exposed surface area.

- Exposed Aggregate Concrete incorporates a wide variety of colorful river stone options.

- Using a smaller, rounder stone one can find colors ranging from blues, to browns, to reds and greens.

- Concrete Red-Mix Suppliers river stone selection and quantities vary.

- A little research between you and your contractor should take place before making final selection.

- The concrete is placed or poured and finished in the same manner as Broom Finish concrete without the final ‘brooming’.

- Immediately upon closing the surface layer of the concrete project a retarding chemical is used on the surface of the concrete which is intended to be exposed.

- This applied chemical ‘slows’ the surface curing process.

- Usually left overnight, the surface of the concrete is washed with water to remove the cement paste on the surface the following day. With the assistance of low pressure washer and soft bristle scrub broom.

- The rest of the concrete is fine as the retarding agent is not deep penetrating and it only affects the upper surface.

- The removal of the cement paste reveals all the beautiful aggregates that otherwise would be hidden in a typical concrete project.

- Once dry and relief joint saw cuts are completed Exposed Aggregate Concrete requires to be sealed.

- Beautiful,

- Unique

- Elegant

- Care with the size aggregate chosen.

- The smaller the better,

- Larger size aggregate, while it may be pretty, may have more space between the stones.

- Dirt and debris to collect,

- Furniture & chairs harder to move,

- Walking in formal wear more difficult.

- Exposed Aggregate Concrete requires initial sealing along with periodic resealing mainenance.

- Decorative Concrete for the most part, pertains to enhancements one can do to existing concrete.

- Although, stamped concrete, by definition, is decorative concrete.

- The Decorative Concrete spoken of here is when acids, stains, sprays, binders and epoxies are in play.

- These are used to make changes to the surface appearance of the current concrete surface.

- Acid Stained Concrete

- Metallic Epoxy

- Vinyl Chip Epoxy

- Polished Concrete

- Troweled Concrete Overlays

- Stamped Concrete Overlays

- Concrete seems to come in all shapes and sizes yet, at it’s core it’s simply three main components.

- The three main components of concrete is Portland cement, aggregate (i.e. rock, sand) and water.

- The paste (cement and water) coats the aggregate (rock, sand) and through hydration the paste hardens, strengthens and creates concrete.

- The key to strong concrete is in the proportions one uses of the three components. Water is the easiest component to over proportion.

- The more water one uses in the mix the more fluid the mixture becomes.

- It becomes easier to mix, work with and – to a point – easier to finish. The downside to over proportioning the water is weaker concrete strength.

- The typical mix ratio of concrete is 10 to 15 percent cement, 60 to 75 percent aggregate and 15 to 20 percent water.

- The intended use for the concrete, budget and personal taste are determining factors as to which concrete finish is perfect for your concrete project.

Exposed Aggregate Concrete Finish

Exposed Aggregate Concrete Benefits:

Exposed Aggregate Concrete Drawbacks:

Decorative Concrete Finish

(Bonus 5th Type of Concrete Finish – Technically)

Common styles or types of Decorative Concrete are:

What IS Concrete?

Here’s a brief synopsis of what concrete actually is.